Overview

Construction background: At present, our country is in the period of rapid development of urbanization. National government has issued a number of regulations and policies to promote the construction of comprehensive urban urban utility tunnel. Comprehensive utility tunnel, also known as integrated urban under ground pipeline, means to build a underground tunnel in city to integrate all kinds of engineering pipelines such as electric power, communication, gas, heat supply, water supply and drainage one tunnel. There are special maintenance port, hoisting port and monitoring system to implement unified planning, design, construction and management. This is the important infrastructure and "lifeline" to ensure the operation of the city.

Comprehensive utility tunnel construction implements the orderly entrance for various important urban pipelines such as water supply and drainage, gas, heating, electricity, communication, radio, television and industry, solves the difficulties in the management of many government departments, multi jurisdictions and multi application units, and greatly improves urban water-logging, "road zipper" project and low utilization of underground space in city.

The above basic characteristics determine the importance of comprehensive utility tunnel. The basic requirements of comprehensive utility tunnel is based on these characteristics.

1. Requirement for tunnel environment. There are many professional urban engineering pipelines in the comprehensive utility tunnel which are important for the safety of city. Thus the priority requirement is to provide a good environment for the pipelines in utility tunnel.

2. Personnel safety requirement. There are regular inspection personnel and irregular installation and maintenance personnel to enter the utility tunnel. Thus suitable working environment for these personnel is one of the basic requirements for utility tunnel.

3. Emergency treatment requirement. Comprehensive utility tunnel is a public environment for various pipelines where there are possibilities of single pipeline accident such as water pipe burst and gas pipeline leakage. For this reason, there must be emergency treatment solution in comprehensive utility tunnel. The purpose is to find an accident in time when an accident occurs in a pipeline, reduce the scope of the accident and effectively protect other normal running pipelines from being affected.

4. Daily management and operation management requirement. The scale of comprehensive utility tunnel is increasing which accommodates a variety of pipelines. Therefore, the management of operation and maintenance is difficult. This requires to establish a management system for utility tunnel so as to improve the management level and provide better service for safe operation.

Comprehensive utility tunnel needs to be equipped with monitoring alarm system and operation and maintenance management system basic on the above requirements, and set it closely around these key requirements.

Design content

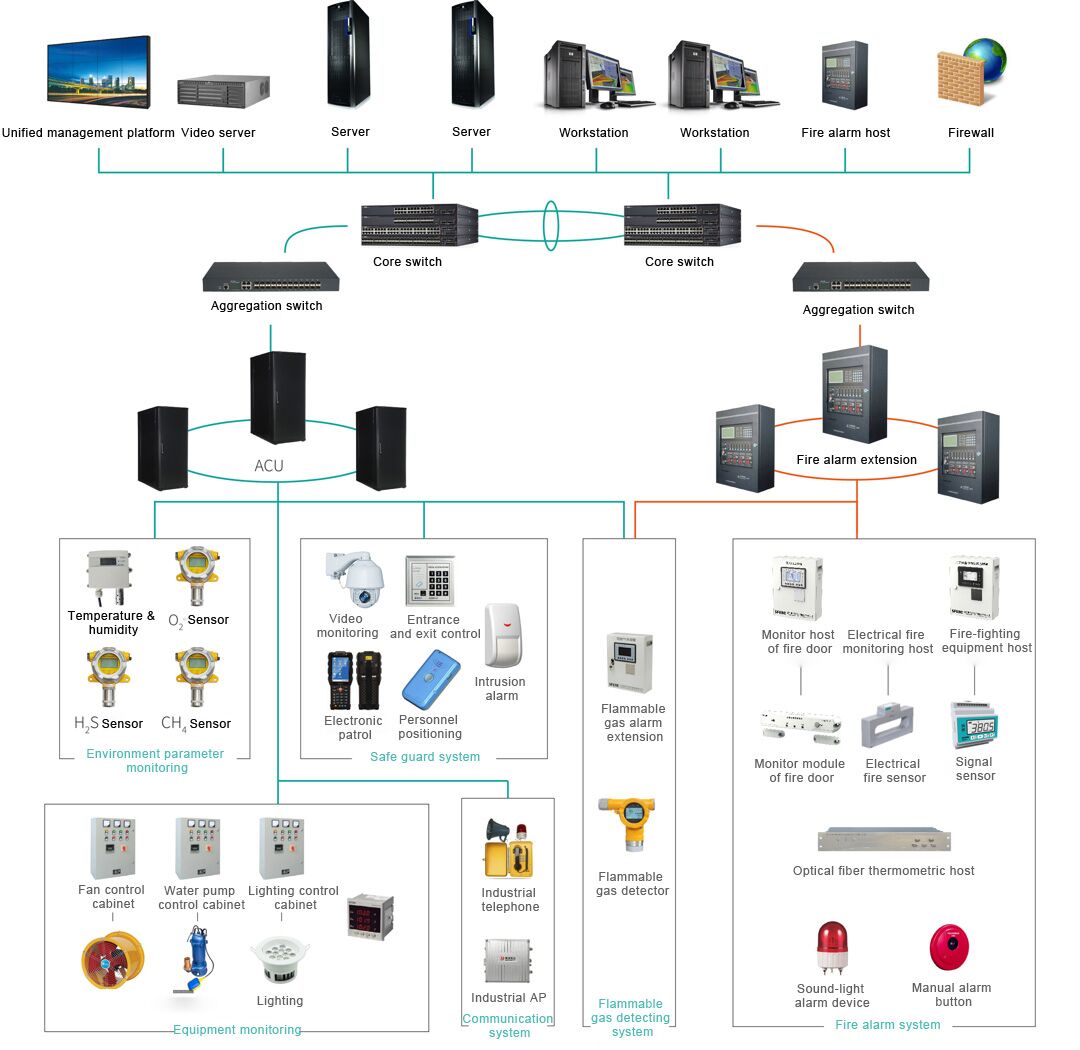

Monitoring alarm system and operation and maintenance management system of utility tunnel are composed of unified management platform, communication controlling network, environment and equipment monitoring system, safety and protection system, communication system and automatic fire alarming system. Communication controlling network adopts optical fiber ring network and fire fighting network. Various professional systems access monitoring centers through special networks to implement integration with unified management platform.

Design concept

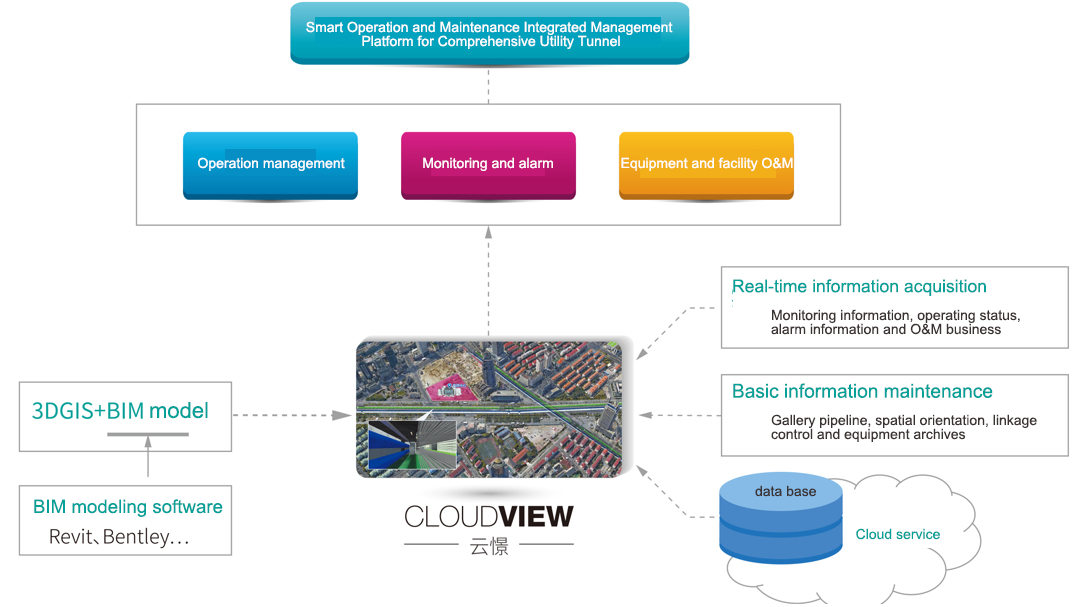

Sfere smart operation and maintenance unified management platform is based on the design of Cloud Architecture. the functions of status monitoring, remote controlling, alarm/fault processing and analysis of system equipment are realized by using the technology of Internet of things. The 3DGIS+BIM engine is built in the platform to achieve seamless and undamaged information integration between 3DGIS and BIM so as to provide storage, query, spatial location, spatial analysis and release services for data such as geographic information, urban terrain and building model. Based on the unified transmission network and communication interface, the platform takes three dimensional integrated space as the carrier to integrate the environmental quality parameters of the utility tunnel and the monitoring information of the ancillary facilities, and realize the monitoring and alarming function. The management process fine controlling of operation and maintenance of utility tunnel is built based on the BIM model and attribute so as to realize the integrated design of facilities operation and maintenance and operation management.

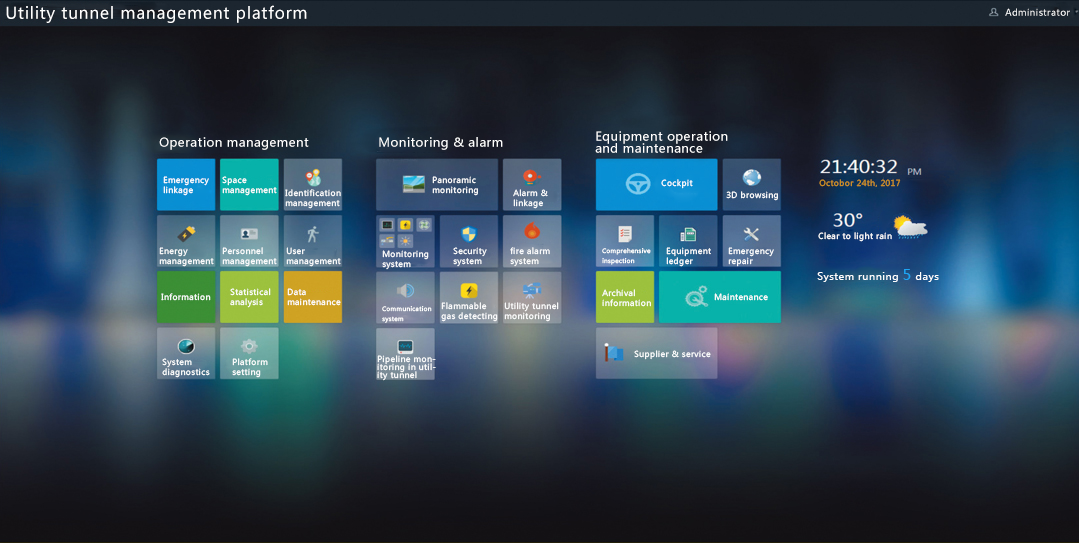

The platform is aimed at ensuring the safe, stable and efficient operation of utility tunnel. Combining the requirements of operation and maintenance division, the system is designed as three modules of equipment and facilities operation and maintenance, monitoring and alarm, and operation management. The operation and maintenance of equipment and facilities module is mainly focused on routine inspection, equipment and facilities maintenance, equipment files and management system requirements, technical standards and operation procedures management functions; The monitoring and alarm module is mainly applied for the functions of real-time monitoring, alarm processing and linkage control of auxiliary equipment and facilities in utility tunnel; operation management module is mainly used for user management, tunnel space usage analysis, emergency plan simulation and emergency linkage management, statistical analysis of operation status and energy consumption analysis.

Unified and integrated information portal: It is a comprehensive information portal which integrates monitoring and alarm management, equipment management, inspection management, maintenance and system diagnosis with the realization of information centralization, data tracing, and process reminding. The interface of other new utility tunnels and pipeline units is reserved to support the construction of newly built and added utility tunnels.

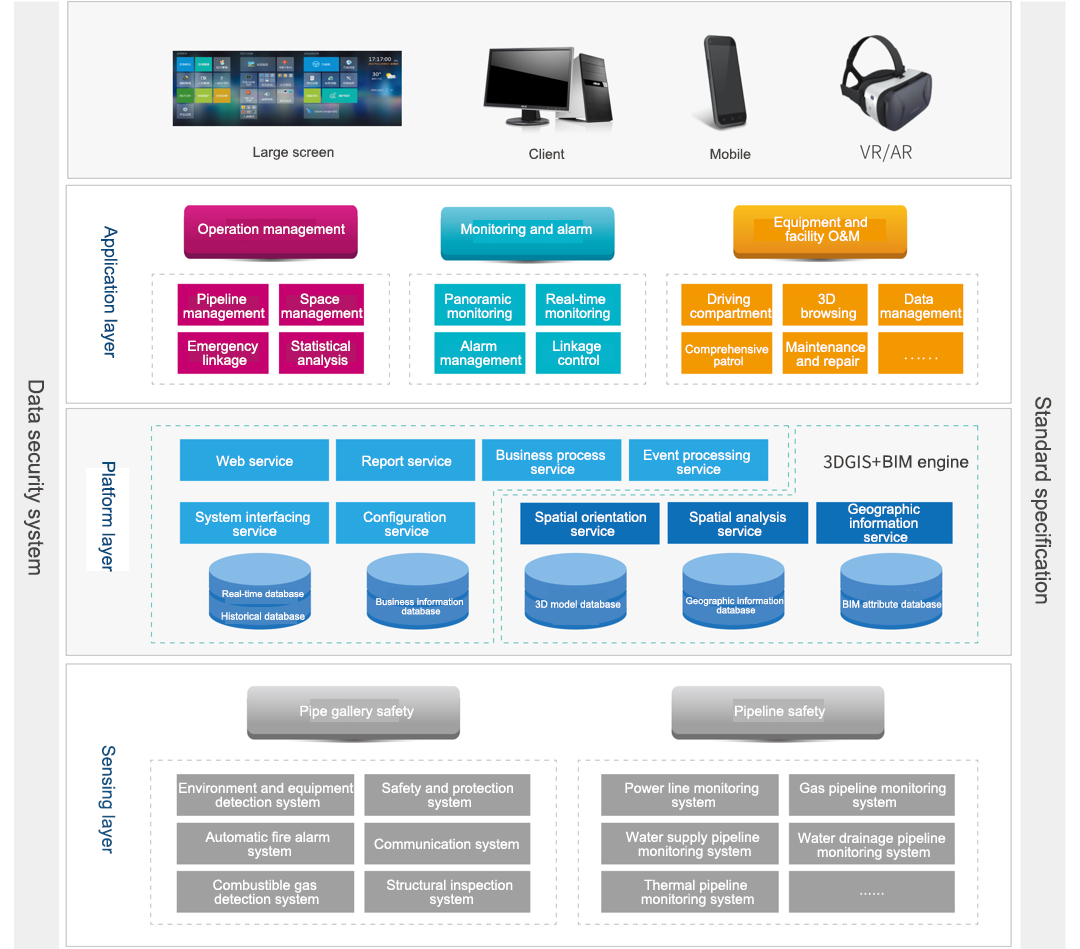

Platform architecture

Perceptual layer collects the operating status information of the environment, auxiliary facilities and professional pipelines, as well as the external environment information of utility tunnel through IP ring network and communication interface, and provide uploading channel for alarm linkage command so as to realize the organic integration of each subsystem.

Platform layer provides business support environment for the upper layer application, realizes unified storage service, integrates 3DGIS+BIM engine, provides spatial location, spatial analysis and publishing services, and achieves business processing logic and system external connection.

Application layer deploys related application modules in B/S mode, provides users with interactive interfaces, achieves related business operations, and presents through large monitoring screen, workstation and mobile terminals.

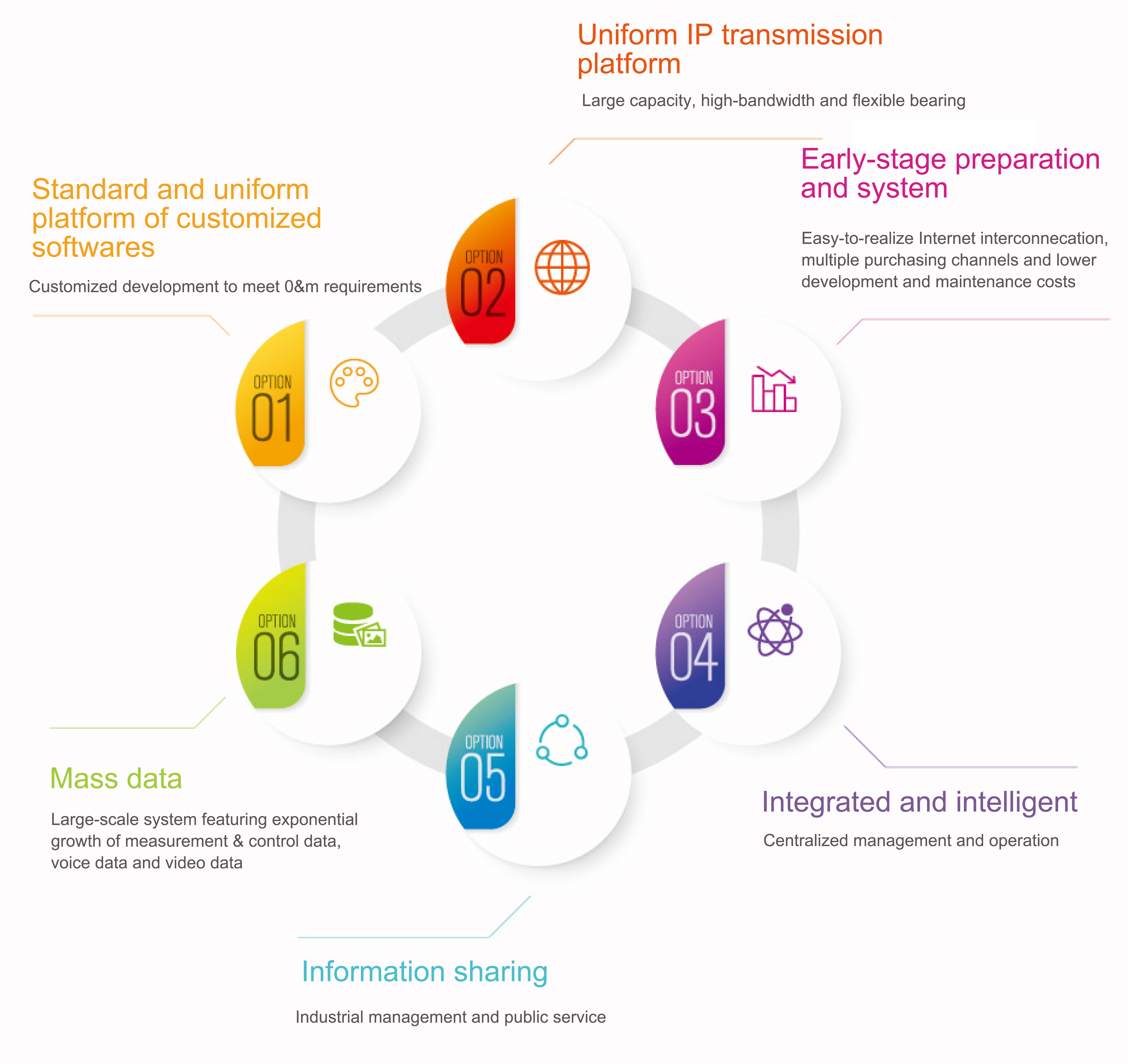

Platform Features

Detailed Design

Monitoring and Alarming

Monitoring and Alarming

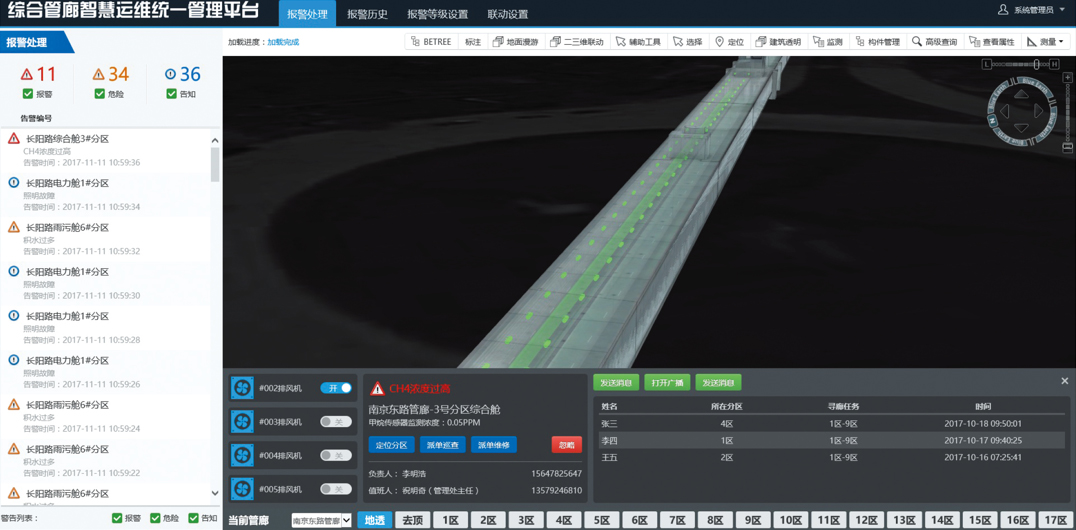

Monitoring and alarming module is mainly used for real-time monitoring, alarm processing and linkage control of utility tunnel body and auxiliary equipment and facilities, and it integrates signal data from systems of environment and equipment monitoring, safety protection, communication, fire alarming and combustible gas. In addition, it could realize panoramic display of monitoring data, fast processing of alarming signals and precise spatial positioning of equipment through setting of linkage control strategies and pre-warning and alarming thresholds, and display of level of component specified by data. It is also equipped with the function of accessing pipeline monitoring data, which provides support for the operation and maintenance of utility tunnels and pipelines and accident disposal.

Panoramic Monitoring Module

This module could realize linkage query and browse of monitoring data of utility tunnels through the integration of remote sensing map and utility tunnel monitoring system, which does a favor for monitoring personnel to get real-time operating conditions of utility tunnels.

Alarming and Linkage Module

This module is specially designed for utility tunnels which are characterized by narrow space, various equipment and complex linkage between systems. It could combine the alarming data with BIM module through 3D visualization technology to dynamically display the location of alarming points in utility tunnels. In addition, it could realize the linkage of associated equipment as per the linkage strategies preset by the system.

Environment and Equipment Monitoring Module

This module is used to carry out the whole-process monitoring of parameters and states of environment and equipment throughout the comprehensive utility tunnels, and provide precise location of accident site and failure equipment for operators on duty through binding the real-time monitoring data and models with components so as to accelerate troubleshooting and disposal of emergencies and ensure the normal operation of utility tunnels.

Power Supply and Distribution Management Module

This module is used to manage the monitoring data of substations in utility tunnels and power and distribution systems in fire zones, monitor the parameters of incoming and outgoing circuits of power and distribution systems, such as voltage, current and power, and the closing and opening state of switches, and creates corresponding operation tables based on the above data so as to comprehensively master the quality of power supply; it could also provide 3D visualization display of conditions of power supply and distribution equipment and route conditions of pipelines through BIM model, and real-time display of current power, total electricity, current and voltage.

Safety Protection Module

This module is used to carry out the whole-process monitoring of personnel throughout the comprehensive utility tunnels, and provide precise location of personnel in the utility tunnels for operators on duty through combining the real-time video data and location data of personnel in the utility tunnels with space technologies so as to accelerate troubleshooting and disposal of emergencies and ensure the normal operation of utility tunnels.

Communication Module

This module is used for scheduling of personnel throughout the comprehensive utility tunnels and to ensure the safe and orderly operation through combining fixed communication and wireless communication with maintenance and patrol inspection.

Fire Alarm Module

This module is used to realize the all-round monitoring of fire throughout the comprehensive utility tunnels. It could detect the abnormal conditions and potential fire risks as soon as possible through the monitoring of utility tunnels by smoke and temperature sensing cables. In addition, it could provide information required for timely evacuation and processing through precisely locating the potential fire risks, which is supported by optical fiber positioning technology (ODTR).

Operation and Maintenance

Operation and Maintenance

The operation and maintenance module of equipment and facilities is mainly used to perform services such as routine inspection, maintenance of equipment and facilities and management of equipment files and management system requirements, technical standards and operation procedures. The maintenance and management process for equipment and facilities in utility tunnels is sorted and prepared according to the three modes of routine maintenance, equipment maintenance and emergency repair to realize the visual location, relevance query and refined maintenance and management of facilities and equipment in 3D mode.

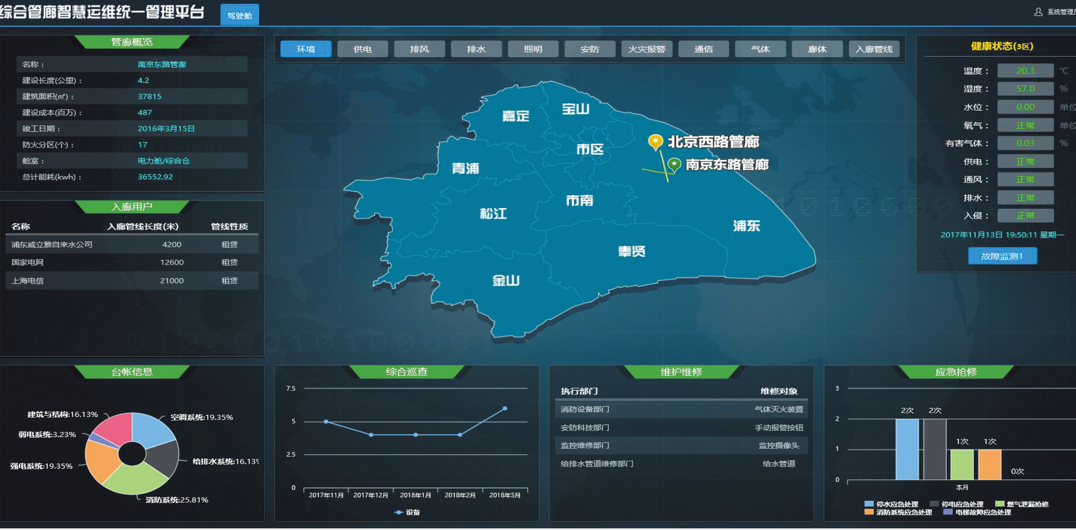

Cockpit Module

This module is used to provide the O&M unit with the overall view of operation and maintenance of equipment and facilities in utility tunnels, which could improve the overall management.

The centralized view that is used to visualize the overall O&M conditions of utility tunnels presents the general condition of utility tunnels, health conditions, user information, equipment ledger information, inspection information and O&M information to O&M personnel in an uniform and integrated mode for easy query, browsing and processing.

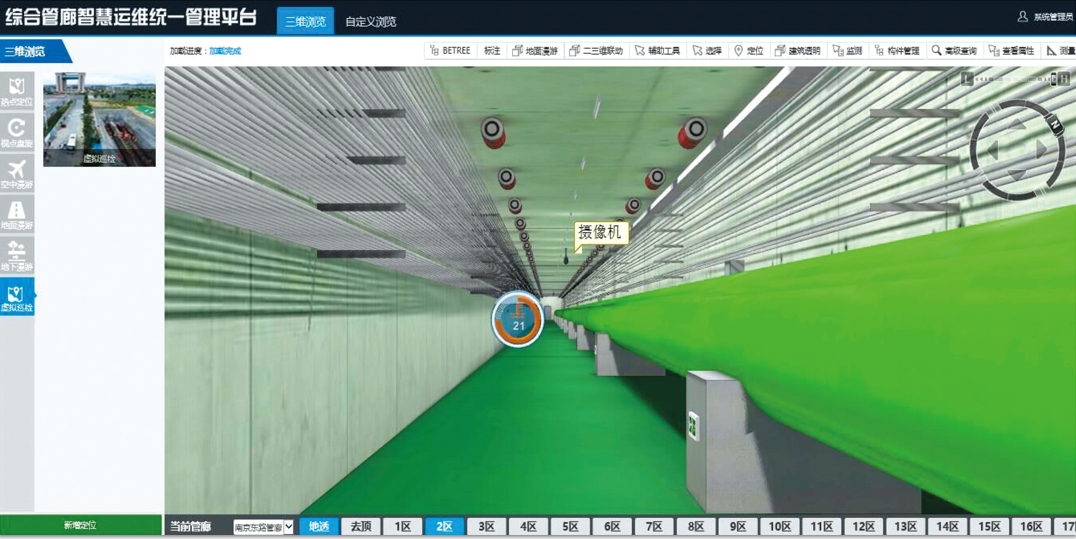

3D Browsing Module

This module is used to show the full view of utility tunnels from multiple dimensions of air, ground and underground, and realize browsing from outdoor to indoor, from ground to underground. It also enables component-level retrieval of information of tunnel bodies, pipelines and ancillary facilities. What’s more, it supports virtual inspection and one-touch virtual query and browsing, to shorten the actual access and inspection time of the O&M personnel. It can be associated with the equipment coding system for utility tunnels to achieve positioning roaming.

Equipment Management Module

This module is used to manage equipment ledger and spare parts and serves as the basic knowledge database for operation and maintenance of equipment and facilities, with a management range covering the whole life cycle from equipment warehousing, installation, operation, maintenance to scrapping. It could also be used to establish the unified equipment asset classification standard and equipment asset coding standard, and form complete equipment asset ledgers based on these standards, to ensure the centralized, systematic and standardized construction of assets and equipment management. Besides, it could categorize the information of different devices into several types such as static, dynamic, real-time and unstructured information according to the information elements, and create knowledge databases with the information generated in the whole life cycle of equipment, to provide auxiliary data support for device management analysis, device reliability and economy.

Comprehensive Inspection Module

This module is used to regularize the operations of managers and inspectors of utility tunnels during routine inspection such as investigating regular potential danger, recording potential danger type (if any), confirming the potential danger level and reporting timely through the establishment of a comprehensive inspection system including work order issuing, on-site inspection, event confirmation, task totaling. It could also generate statistical statements of inspection to provide auxiliary data support for the safety of the utility tunnels and pipelines and the reliability of ancillary facilities.

Maintenance Module

This module is used to regularize the operations of managers and maintenance personnel of utility tunnels during maintenance such as investigating regular potential danger, recording potential danger type (if any), confirming the potential danger level and reporting timely through the establishment of a comprehensive maintenance system including work order issuing, on-site inspection, event confirmation, task totaling. It could also generate statistical statements of maintenance to provide auxiliary data support for the safety of the utility tunnels and pipelines and the reliability of ancillary facilities.

Operation and Maintenance

Operation and Maintenance

Monitoring and alarming module is mainly used for real-time monitoring, alarm processing and linkage control of utility tunnel body and auxiliary equipment and facilities, and it integrates signal data from systems of environment and equipment monitoring, safety protection, communication, fire alarming and combustible gas. In addition, it could realize panoramic display of monitoring data, fast processing of alarming signals and precise spatial positioning of equipment through setting of linkage control strategies and pre-warning and alarming thresholds, and display of level of component specified by data. It is also equipped with the function of accessing pipeline monitoring data, which provides support for the operation and maintenance of utility tunnels and pipelines and accident disposal.

User Management Module

This module is used to provide functions such as management of pipeline access process management, maintenance of information of units with the pipeline ownership, professional management and regulation of pipelines and management of pipeline data based on the professional process of pipeline access business, which realizes the business connection between the management unit of utility tunnels and units with the pipeline ownership.

Space Management Module

This module is corresponding to user management, and used to sort out and arrange the limited installation positions of pipelines in utility tunnels according to the change of business demand, to optimize the utilization rate of space.

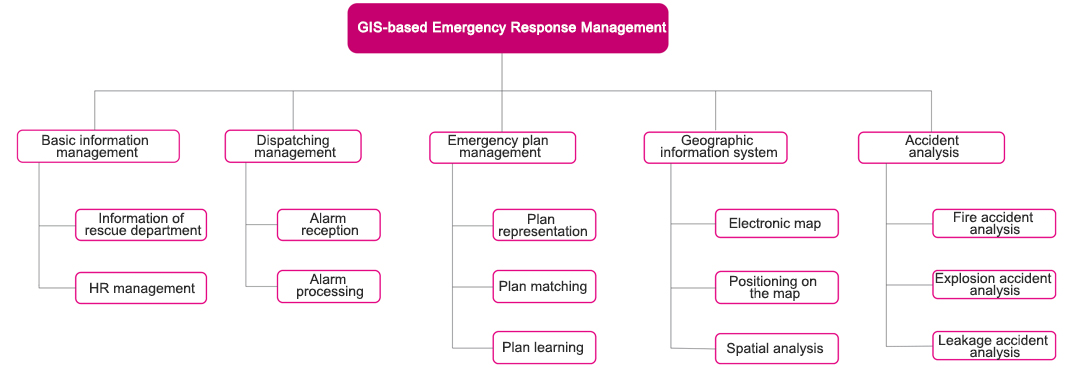

Emergency Linkage Module

IT-based processing

In case of accidents, emergency response process and measures necessary to be implemented would be informationized to ensure that there are enough supports for the confirmation during and after accidents and to prevent missing.

Automation of process operation

In the whole process of emergency command, the confirmation of pipeline units and various data and control of various devices could all be realized by this software.

Electronization of emergency files

After the emergency command, the recorded data could not only be queried and analyzed, but also be used as reference for hazard prediction in big data analysis.

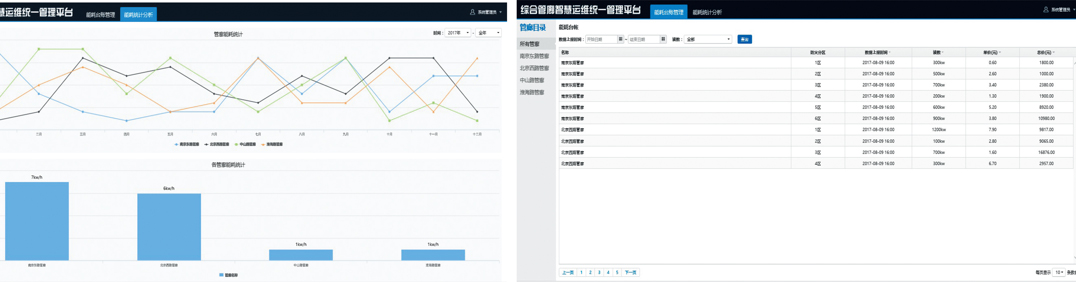

Statistical Analysis Module

The module is used to collect O&M data of utility tunnels and operation status of equipment, carry out multi-dimensional statistical analysis of utility tunnels from equipment operation and alarm, capture the operation tendency of utility tunnels, detect potential dangers in time, and take appropriate measures to eliminate dangers.

It also can improve the overall operation efficiency of utility tunnels through improving the utilization rate of utility tunnels, reducing the failure rate of equipment and optimizing the matching of personnel and materials based on the statistical data of pipeline access, occupancy of space, personnel scheduling and maintenance conditions.

Energy Consumption Management Module

The main energy consumed by the body of utility tunnels is electric energy, and the main consumers are drainage and ventilation equipment, lighting equipment and so on. This module is used for energy statistics as per the classification of utility tunnels, partitions and equipment through on-line electricity acquisition, and displays the statistical results in histogram, pie chart, trend curve and form for contrastive analysis. In this way, operators could comprehensively master the overall consumption and efficiency of energy, and make more proper and effective decision on the adjustment of operation mode of relevant equipment, the safe, stable and high-efficiency operation of utility tunnels and energy-saving reform in the future.